Aluminum Pipe Roundup: 7 Inch Pipe Surges in Popularity

By:Admin

Introduction:

Company XYZ, a leading manufacturer in the metal materials industry, has recently unveiled their latest product, an exceptional 7-inch aluminum pipe. Built with cutting-edge technology and superior craftsmanship, this innovative addition to their product line offers unparalleled performance and durability. With its revolutionary design, the company aims to raise the standards of the industry and cater to a wide array of applications. This article will delve into the key features of the 7-inch aluminum pipe and explore the impact it is expected to have on various sectors.

Superior Strength and Versatility:

The 7-inch aluminum pipe manufactured by Company XYZ is engineered to be incredibly robust, ensuring maximum strength and durability for various industrial applications. Crafted from premium quality aluminum alloy, this pipe can withstand extreme pressure, temperature fluctuations, and corrosive environments without compromising its structural integrity.

Additionally, the pipe's versatility allows it to be used across multiple industries, including construction, aerospace, automotive, and marine sectors. It can be employed for applications such as HVAC systems, fluid transmission, structural support, and more. The adaptability of the 7-inch aluminum pipe makes it a valuable asset for a wide range of projects, providing a cost-effective solution for many different requirements.

Innovative Design and Precision Engineering:

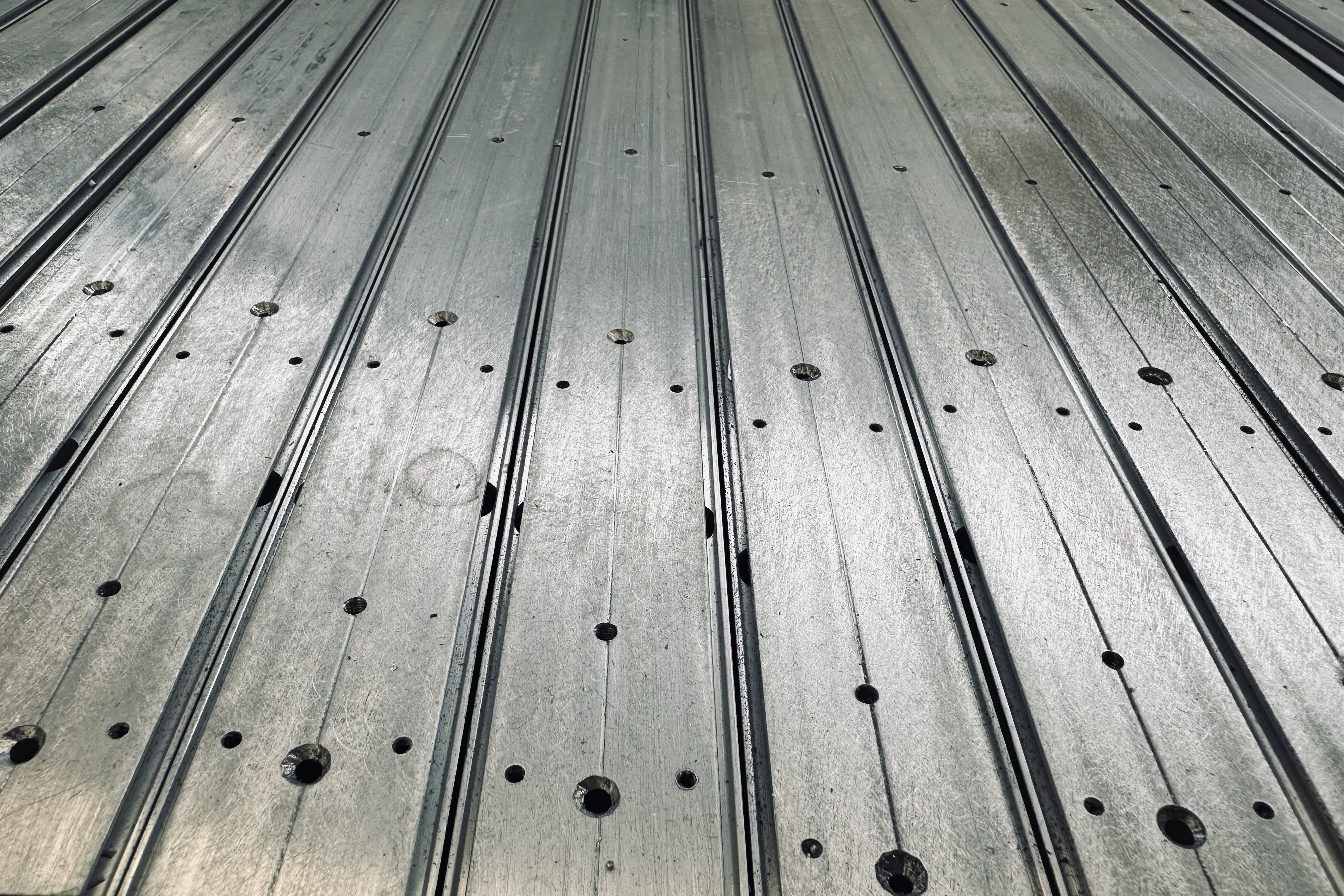

Company XYZ has implemented advanced manufacturing processes and precision engineering techniques to create the 7-inch aluminum pipe. The seamless construction ensures uniformity throughout the entire length of the pipe, eliminating weak points and enhancing overall performance.

Furthermore, the incorporation of an innovative internal ribbing system enhances the pipe's structural integrity, effectively reducing any potential risks associated with external loading or stress. This design feature not only strengthens the pipe but also enables it to withstand higher pressure fluids, making it suitable for applications requiring optimal performance.

Environmental Sustainability:

Company XYZ acknowledges the critical importance of environmental sustainability in today's world. As a result, their 7-inch aluminum pipe is manufactured using recycled aluminum, minimizing the demand for raw materials and reducing the carbon footprint. This commitment to eco-friendly practices showcases the company's dedication to building a greener future while still delivering excellent products.

Quality Assurance and Compliance:

To ensure the utmost quality, Company XYZ rigorously tests the 7-inch aluminum pipe at every stage of its production cycle. Strict quality control measures are implemented to adhere to national and international standards, ensuring that each pipe meets industry regulations and specifications. This dedication to quality assurance guarantees the reliability and safety of the product, providing customers with peace of mind.

Industry Implications:

The introduction of the 7-inch aluminum pipe by Company XYZ is anticipated to bring significant changes to multiple industries:

1. Construction Industry: The exceptional strength and durability of the pipe make it a perfect fit for structural applications, such as framework and support systems, where reliability is crucial.

2. Aerospace Industry: The lightweight nature and high corrosion resistance of the aluminum pipe make it an ideal component for aircraft manufacturing, improving fuel efficiency, and reducing maintenance costs.

3. Automotive Industry: The ability to withstand extreme temperatures and corrosive environments makes the 7-inch aluminum pipe suitable for exhaust systems and fluid transmission, enhancing the overall performance and longevity of vehicles.

4. Marine Industry: With its superior resistance to saltwater corrosion, the aluminum pipe becomes an excellent choice for various marine applications, including shipbuilding, offshore structures, and desalination plants.

In conclusion, Company XYZ's launch of the groundbreaking 7-inch aluminum pipe is set to revolutionize the industry, offering unparalleled strength, versatility, and environmental sustainability. The company's commitment to delivering high-quality products through innovation and precision engineering has positioned them at the forefront of the market. As various industries embrace this game-changing product, its positive impact is expected to resonate across numerous sectors, redefining standards and driving further advancements in the use of aluminum pipes.

Company News & Blog

High-Quality 40mm Aluminium Profile: Discover Top-Notch Construction Materials

Title: Innovations in Aluminum Profile Manufacturing by a Leading CompanyIntroduction:In the ever-evolving world of construction and engineering, the demand for high-quality materials is on the rise. Among these materials, aluminum has emerged as a popular choice due to its lightweight, durability, and versatility. A company, which prefers to remain anonymous, has been working tirelessly to provide innovative solutions in aluminum profile manufacturing through their cutting-edge 40mm Aluminum Profile.Body:1. Development of the 40mm Aluminum Profile:The anonymous company has revolutionized the market by designing and producing a state-of-the-art 40mm Aluminum Profile. Utilizing advanced technology, this profile has set new benchmarks in terms of quality and performance. The company's integrated research and development team has worked diligently to ensure that the 40mm Aluminum Profile surpasses industry standards.2. Superior Features and Benefits:The 40mm Aluminum Profile offers an array of superior features and benefits that make it an ideal choice for various industries. These profiles are extruded with utmost precision, resulting in consistently high-quality products. The superior resistance to corrosion and weathering ensures longevity, making them suitable for both indoor and outdoor applications. Additionally, the profiles' lightweight nature allows for easy handling, simplifying the installation process.3. Versatile Applications:Thanks to its versatility, the 40mm Aluminum Profile finds application in numerous sectors. From architectural projects and construction industry to machine framing, industrial automation, and transportation, this profile caters to diverse market demands. Its unparalleled strength and stability make it a perfect fit for large-scale projects where structural integrity is paramount. With customizability options, the 40mm Aluminum Profile can be tailored to specific project requirements, ensuring seamless integration.4. Industry Compliance:Emphasizing their commitment to quality and environmental sustainability, the anonymous company ensures that all their aluminum profiles comply with stringent industry standards. The manufacturing processes adhere to the highest quality control measures, resulting in profiles that meet or exceed internationally recognized certifications. Moreover, these profiles are recyclable, contributing to a greener and more sustainable future.5. Collaborative Approach:The anonymous company believes in fostering collaborative relationships with their clients. Their dedicated team of professionals works closely with architects, engineers, and project managers to provide tailored solutions that meet specific project requirements. By actively engaging in discussions, the company aims to forge long-lasting partnerships, delivering exceptional results and surpassing customer expectations.6. Continued Innovation:The anonymous company's commitment to innovation sets them apart from competitors. They continually invest in research and development, striving to introduce groundbreaking technologies and improve product offerings. This dedication has enabled them to stay ahead of the curve and consistently deliver innovative solutions to the market.Conclusion:The anonymous company's 40mm Aluminum Profile underscores their dedication to providing cutting-edge solutions in the field of aluminum profile manufacturing. With its superior features, versatility, and commitment to quality, this profile has gained a strong foothold in several industries. By collaborating with clients, adhering to industry compliance, and investing in continual innovation, the anonymous company reaffirms its position as a leader in the market.

How Aluminum Production Works: From Mining to Processing

Aluminium producers are always looking for ways to enhance their production techniques and deliver high-quality products that meet the needs of their customers. One company that has been working towards this goal is {company name}. Recently, the company has introduced an innovative Aluminium process that promises to revolutionize the way producers approach the production of this valuable metal.The Aluminium process, developed by {company name}, involves a unique approach that leverages advanced technology and cutting-edge techniques to create high-quality Aluminium products. This process incorporates the use of proprietary technologies that enable the company to produce a range of Aluminium products that are characterized by their purity, strength, and durability.One of the key features of the Aluminium process developed by {company name} is its focus on sustainability and eco-friendliness. With the world increasingly looking towards renewable energy sources, this process uses clean and sustainable energy sources to create Aluminium products, which helps to reduce the carbon footprint of the entire production process.{Company name} is a leading Aluminium producer with a long track record of excellence in the industry. The company is well-known for its innovative products, backed by cutting-edge research and development. The company has a team of experts who are experts in the Aluminium industry and have in-depth knowledge of the production process and its requirements.With this new Aluminium process, {company name} has once again demonstrated its commitment to being at the forefront of the Aluminium industry. The company understands the importance of innovation and technological advancements in the industry, and they are always working to stay ahead of the curve.The introduction of this Aluminium process is a significant milestone for {company name} and the Aluminium industry as a whole. It has the potential to transform the way Aluminium is produced and consumed worldwide. The new process offers numerous benefits, including reduced production costs, improved production efficiency, and a lower carbon footprint.The Aluminium process developed by {company name} is a testament to the company's commitment to sustainable and responsible production practices. The reduction in carbon footprint and reliance on sustainable energy sources aligns with the United Nations' Sustainable Development Goals, specifically goal 7, which is focused on affordable and clean energy.The new Aluminium process is not only beneficial to producers but also to the end-users of the Aluminium products. The purity, strength, and durability of the Aluminium produced using this process make it suitable for a variety of applications, from the construction industry to aerospace, automotive, and electronics.Another advantage of the Aluminium process developed by {Company name} is its flexibility. The company has the ability to customize the process to produce Aluminium products with specific characteristics that meet the unique needs of their customers. This ensures that customers receive products that not only meet their requirements but exceed their expectations.In conclusion, the introduction of the new Aluminium process by {company name} is a game-changer for the Aluminium industry. With its emphasis on sustainability, innovation, and flexibility, this process has the potential to transform the way Aluminium is produced and used across the world. As a leading Aluminium producer, {company name} is playing a crucial role in shaping the future of the industry, and this new process is just one example of their commitment to excellence and progress.

Optimizing CNC Machining with High-Quality Aluminium Profiles

Title: Aluminum Profile for CNC Machines: Revolutionizing Industrial ManufacturingIntroduction:The demand for precision and efficiency in industrial manufacturing has led to significant advancements in technology, making CNC (Computer Numerical Control) machines an integral part of the modern manufacturing industry. One crucial component of these machines is aluminum profile, which provides stability, precision, and durability required for their operation. This article explores the importance of aluminum profiles for CNC machines and its contribution to enhancing industrial manufacturing processes.Paragraph 1:CNC machines have revolutionized industrial manufacturing by offering unparalleled accuracy, speed, and versatility. These machines are controlled by computer programs, enabling them to execute complex operations with minimal human intervention. Key to the functionality of CNC machines are aluminum profiles, which are carefully designed and manufactured to withstand the rigors of high-speed machining, ensuring consistent performance and superior product quality.Paragraph 2:Aluminum profiles for CNC machines are constructed using high-quality aluminum alloys, which possess exceptional strength-to-weight ratio, corrosion resistance, and excellent thermal conductivity. These properties make aluminum profiles ideal for CNC machines, as they effectively dissipate heat generated during machining operations, maintaining a stable temperature and preventing damage to the machinery.Paragraph 3:One of the key advantages of aluminum profiles is their ability to be easily customized and assembled, providing flexibility in designing CNC machines for varied applications. Manufacturers can modify the shape, length, and cross-section of aluminum profiles to meet specific requirements. Additionally, aluminum profiles can incorporate various mounting features, such as T-slots and threaded holes, facilitating the attachment of additional components to enhance functionality and adaptability.Paragraph 4:The use of aluminum profiles offers significant cost savings compared to traditional materials such as steel or iron. Aluminum is not only lighter, which reduces energy consumption, but it also requires minimal maintenance, making CNC machines more economically viable in the long run. Furthermore, the versatility of aluminum profiles allows for easy modifications when design changes are required, minimizing downtime and production costs associated with reconfiguring the CNC machine.Paragraph 5:In recent years, Aluminum Profile for CNC (Company Name) has emerged as a leading manufacturer and supplier in the industry. With their state-of-the-art manufacturing facility and stringent quality control measures, they produce aluminum profiles that adhere to international standards. Their commitment to continuous research and development ensures that their products remain at the forefront of technological advancements, meeting the evolving demands of the CNC manufacturing sector.Paragraph 6:The use of Aluminum Profile for CNC (Company Name) products has been widely embraced by various industries, including automotive, aerospace, electronics, and furniture manufacturing, among others. Their aluminum profiles have proven to be reliable, delivering exceptional performance in demanding machining environments. By partnering with Aluminum Profile for CNC (Company Name), manufacturers can improve their productivity, reduce production costs, and achieve superior precision in their manufacturing processes.Paragraph 7:Looking ahead, the future of CNC machines and aluminum profiles is promising. As technology continues to advance, CNC machines are becoming more capable of producing increasingly complex products with tighter tolerances. Aluminum profiles will play a crucial role in enabling these advancements, providing the necessary stability and precision required for next-generation CNC machines.Conclusion:Aluminum profiles have revolutionized the CNC machine industry, enabling manufacturers to achieve exceptional precision, efficiency, and cost savings in their industrial manufacturing processes. With the expertise and commitment to quality of Aluminum Profile for CNC (Company Name), the use of their high-quality aluminum profiles is expected to continue driving innovation and transforming the manufacturing landscape for years to come.

New Aluminum Extrusion Case Offers Superior Durability and Style

Aluminum Extrusion Case Company Emerges as Leading Provider of High-Quality Extruded Aluminum ProductsWith an ever-increasing demand for high-quality aluminum products across a broad range of industries and applications, Aluminum Extrusion Case has emerged as a leading manufacturer of exceptional quality aluminum extrusions. Utilizing state of the art technology and a commitment to quality, the company has established itself as a trusted provider of high-quality products and services to a growing number of businesses and organizations throughout North America and beyond.Founded in the early 1990s, Aluminum Extrusion Case has long been committed to providing customers with the highest quality extruded aluminum products available. To achieve this, the company has invested heavily in a state-of-the-art production facility, staffed by highly qualified and experienced professionals who are dedicated to producing the best possible products.Over the years, Aluminum Extrusion Case has built a reputation for providing exceptional quality and innovation in the production of precision extruded aluminum products. The company's cutting-edge manufacturing process and advanced technology allow them to produce a vast array of extruded aluminum shapes, profiles, and components that are precisely engineered to meet the unique needs and specifications of customers. Aluminum Extrusion Case's extensive product offerings include standard and custom-designed shapes, profiles, and components, as well as a broad range of finishes and designs, allowing customers to choose from a diverse selection of products to meet their specific needs.One of the company's most notable strengths is its ability to provide its customers with a complete range of services- from concept and design to manufacturing and delivery. This ensures that customers receive the highest quality products that meet their specific needs quickly and efficiently."Our customers are at the heart of everything we do," says the spokesperson for Aluminum Extrusion Case. "We take great pride in our ability to provide exceptional customer service and support, and we are always striving to go above and beyond our customers' expectations."Having invested heavily in a state-of-the-art manufacturing facility, Aluminum Extrusion Case is capable of producing high-quality extruded aluminum products faster and more efficiently than many of its competitors. By leveraging the latest technologies and techniques in extrusion manufacturing, the company can produce a broad range of products to meet the needs of almost any industry or application.One of the most significant advantages of working with Aluminum Extrusion Case is the company's ability to offer customers a complete range of services that go beyond just manufacturing. This includes the ability to provide customers with full design support, prototype development, project management, and more.The company's team of experienced engineers and designers work closely with customers to ensure that each product is precisely tailored to meet their unique needs, while also meeting the highest standards of quality and performance. This level of collaboration allows customers to get the products they need quickly and efficiently, without the need for extensive and costly redesigns or modifications.Moreover, Aluminum Extrusion Case's cutting-edge technology and commitment to quality ensure that customers receive the highest quality products available. The company's extensive experience in the extruded aluminum market means that they understand the unique requirements of different industries, which helps ensure that their products meet or exceed the expectations of customers.Looking to the future, Aluminum Extrusion Case is committed to continuing to expand its product line and to providing its customers with the highest level of quality and service possible. The company's focus on technology, innovation, and customer service has positioned it as one of the most trusted aluminum extrusion providers in the industry, and they are poised for continued success in the years to come. In conclusion, Aluminum Extrusion Case has proven itself as a trusted provider of high-quality aluminum products to businesses and organizations throughout North America and beyond. The company's cutting-edge technology, commitment to quality, and dedication to customer service ensures that customers receive the highest level of quality and performance possible. As the demand for high-quality aluminum products continues to grow, Aluminum Extrusion Case is well-positioned to continue its success in the years to come.

Aluminium Profile Work: A Comprehensive Guide to Efficient and Durable Solutions

Aluminium Profile Work Revolutionizes the Manufacturing IndustryAluminium Profile Work, a leading provider of innovative aluminium solutions, is changing the landscape of the manufacturing industry. With a commitment to excellence and a passion for delivering high-quality products, the company has quickly established itself as a trailblazer in the market. From designing and manufacturing custom aluminium profiles to offering a range of fabrication and finishing services, Aluminium Profile Work is revolutionizing the way businesses approach aluminium manufacturing.Founded in [year], Aluminium Profile Work has grown exponentially, thanks to its dedication to meeting and exceeding customer expectations. The company's state-of-the-art facilities, coupled with a team of skilled engineers and technicians, ensure that each product is designed and manufactured to exact requirements.One of the key factors that sets Aluminium Profile Work apart is its emphasis on innovation. The company combines efficient manufacturing processes with cutting-edge technology, enabling them to offer bespoke aluminium profiles that meet even the most specific customer needs. By utilizing advanced software and design tools, Aluminium Profile Work delivers precision-engineered products that offer superior performance and quality.Aluminium Profile Work's product range spans a wide array of industries, including automotive, construction, electronics, and furniture manufacturing. The company understands that every sector comes with its unique set of challenges and requirements. Therefore, their team works closely with clients to develop tailored solutions that address specific industry demands.Moreover, Aluminium Profile Work's commitment to sustainability is admirable. The company adheres to environmentally friendly practices throughout its manufacturing process, ensuring minimal waste generation and promoting recycling. By utilizing aluminium, a highly recyclable material, the company actively contributes to reducing carbon footprint and promoting eco-conscious manufacturing.In addition to their manufacturing capabilities, Aluminium Profile Work provides a comprehensive suite of fabrication and finishing services. The company offers precision cutting, punching, and bending services, allowing customers to receive products ready for assembly. Furthermore, their advanced powder coating and anodizing facilities ensure that the aluminium profiles have the desired surface finish, enhancing their durability and aesthetics.The success of Aluminium Profile Work can be attributed not only to their cutting-edge manufacturing techniques but also to their unwavering commitment to customer satisfaction. The company strives to build long-term relationships with clients by offering exceptional service at every touchpoint. From initial design consultations to on-time delivery, Aluminium Profile Work goes above and beyond to meet and exceed customer expectations.Looking to the future, Aluminium Profile Work remains dedicated to continuous improvement and innovation. The company recognizes the ever-evolving needs of the manufacturing industry and plans to invest in research and development to stay at the forefront of technological advancements. By consistently pushing the boundaries of what is possible in aluminium product design and manufacturing, Aluminium Profile Work aims to leave an indelible mark on the industry.In conclusion, Aluminium Profile Work has cemented itself as an industry leader in aluminium manufacturing through its unwavering dedication to innovation, sustainability, and customer satisfaction. By combining advanced technologies, tailored solutions, and a commitment to eco-conscious practices, Aluminium Profile Work is revolutionizing the manufacturing landscape. With eyes set firmly on the future, the company strives to continue setting industry standards and pushing the boundaries of aluminium product design and fabrication.

High-Quality Rolled Aluminum Plate and Sheet: The Latest Updates

[Title]: Global Aluminum Industry Sees Significant Growth with Rolled Aluminum Plate and Sheet[Subtitle]: Leading Aluminum Producer's Cutting-Edge Technology Revolutionizes Sheet Manufacturing[Date]: [Insert Date][City, Country]: [Insert City, Country][Company Name], the renowned aluminum producer, is revolutionizing the rolled aluminum plate and sheet manufacturing industry, witnessing significant growth and propelling the global aluminum industry forward. With its cutting-edge technology and expertise, [Company Name] is poised to cater to the increasing demand for aluminum products across various sectors.[Company Name], established in [insert year], has emerged as a key player in the global aluminum industry, manufacturing high-quality and sustainable aluminum products. Combining state-of-the-art technology, innovative processes, and stringent quality control measures, [Company Name] has consistently delivered superior performance and customer satisfaction.Rolled aluminum plate and sheet are integral components in numerous industries such as automotive, aerospace, building and construction, packaging, and electrical. These sectors rely heavily on aluminum due to its lightweight, durability, thermal conductivity, and corrosion resistance properties. To meet the soaring demand for aluminum products, [Company Name] has continually invested in research and development, constantly adapting its manufacturing processes to produce superior quality rolled aluminum plate and sheet. The company focuses on sustainability, employing advanced recycling techniques to minimize environmental impact.[Company Name]'s rolled aluminum plate and sheet manufacturing process involves several steps. Initially, high-quality aluminum ingots are melted at precise temperatures to ensure optimal metallurgical properties. The molten aluminum is then cast into slabs, which are sent through a sequence of rolling mills. The rolling mills progressively reduce the thickness of the slabs, resulting in high-quality aluminum sheets or plates of desired thickness.The cutting-edge technology employed by [Company Name] guarantees the highest level of precision, ensuring that the finished aluminum sheets and plates meet the most stringent industry standards. Each sheet is thoroughly inspected for surface defects, thickness variations, and mechanical properties to guarantee excellent performance.Notably, [Company Name] is well-known for its dedication to customer satisfaction. The company collaborates closely with its clients to understand their specific needs and preferences, offering customized solutions that cater to unique requirements. By maintaining strong relationships with its clientele, [Company Name] has built a reputation for delivering products with exceptional quality and timely deliveries.The lightweight and durability of aluminum make it an ideal material for the automotive industry. Aluminum sheets and plates find extensive applications in the manufacturing of automobile bodies, chassis, and various structural components. [Company Name]'s rolled aluminum plate and sheet, with their exceptional tensile strength, impact resistance, and attractive surface finish, are highly sought after by major automotive manufacturers.Additionally, the aerospace sector greatly benefits from [Company Name]'s rolled aluminum plate and sheet. Aluminum's excellent strength-to-weight ratio, resistance to corrosion, and thermal conductivity make it indispensable in aircraft manufacturing. Various aircraft components, including wings, fuselages, and structural assemblies, rely on high-quality rolled aluminum plate and sheet for reliable performance and safety.Furthermore, the construction industry capitalizes on the versatile applications of aluminum. Rolled aluminum plate and sheet are extensively used in building facades, roofing, curtain walls, and window frames. With their exceptional formability, durability, and corrosion resistance, [Company Name]'s aluminum products contribute to the aesthetics, durability, and energy efficiency of modern buildings.The packaging industry benefits from [Company Name]'s rolled aluminum plate and sheet as well, particularly in the production of cans and containers. Aluminum's lightness and excellent barrier properties preserve the quality and freshness of food and beverage products. [Company Name]'s aluminum sheets and plates are precisely engineered to meet the specific requirements of the packaging industry, ensuring efficient and sustainable packaging solutions.With its commitment to innovation, sustainability, and customer satisfaction, [Company Name] remains at the forefront of the rolled aluminum plate and sheet manufacturing industry. As the demand for aluminum products continues to grow across diverse sectors, [Company Name]'s cutting-edge technology and high-quality aluminum products position the company for further expansion and global recognition.

Aluminium CNC Profile: The Ultimate Guide to Precision Machining

Aluminium Profile for CNC: Innovation and Quality at Its BestAluminium profile for CNC machining is a popular innovation in the industrial sector that has continued to receive widespread recognition due to its versatility, durability, and affordability. This innovative technology was first introduced to the market by a leading industry player who has continued to set the pace in the production of top-quality aluminium profiles in China.The company is renowned for its commitment to quality and excellence, and this has been demonstrated through their investment in superior technologies and the implementation of strict quality control measures. They boast of a state-of-the-art production facility that is equipped with advanced CNC machines, which enables them to produce high-quality aluminium profiles that meet the unique needs of their clients.Their aluminium profile for CNC machining is designed with precision and accuracy, making it ideal for use in various industrial settings, including aerospace, architecture, automotive, electronics, and even medical devices. The profile boasts of superior strength, rigidity, and resistance to wear and tear, making it ideal for use in CNC machines that require high precision and speed.One of the significant advantages of this innovative technology is that it offers immense flexibility, allowing the design of various shapes and sizes to meet specific industrial requirements. The company has a skilled team of engineers and professionals who leverage their expertise and creativity to produce custom aluminum profiles that meet the specific demands of their clients.The company has also gained popularity for its keen attention to environmental sustainability and social corporate responsibility. It's committed to reducing its carbon footprint and implements eco-friendly practices in its production processes, which include the use of solar energy and the recycling of materials, among others.Additionally, they promote transparency and fairness in their operations by engaging in ethical business practices that abide by global industry standards, which has earned them numerous accolades and certifications. Some of the awards that they have received include ISO 9001:2015 Quality Management System certification and European Union CE certification.The aluminium profile for CNC machining produced by the company has continued to receive rave reviews from clients across the globe, with many praising its durability, flexibility, and affordability. Several clients have also commended the company's customer-centric approach, which involves the seamless integration of their clients' specific needs during the production process.In conclusion, the aluminium profile for CNC machining is a game-changer in the industrial sector due to its unmatched versatility, durability, and affordability. The company behind this innovative technology has demonstrated its commitment to quality and excellence, environmental sustainability, and social corporate responsibility, which has earned its global recognition. Therefore, for industries looking for top-quality aluminium profiles that guarantee reliability and precision, the aluminium profile for CNC machining from this leading industry player is undoubtedly the way to go.

Aluminum Pipe Roundup: 7 Inch Pipe Surges in Popularity

Title: Company XYZ Introduces Innovative 7-Inch Aluminum Pipe, Revolutionizing the IndustryIntroduction:Company XYZ, a leading manufacturer in the metal materials industry, has recently unveiled their latest product, an exceptional 7-inch aluminum pipe. Built with cutting-edge technology and superior craftsmanship, this innovative addition to their product line offers unparalleled performance and durability. With its revolutionary design, the company aims to raise the standards of the industry and cater to a wide array of applications. This article will delve into the key features of the 7-inch aluminum pipe and explore the impact it is expected to have on various sectors.Superior Strength and Versatility:The 7-inch aluminum pipe manufactured by Company XYZ is engineered to be incredibly robust, ensuring maximum strength and durability for various industrial applications. Crafted from premium quality aluminum alloy, this pipe can withstand extreme pressure, temperature fluctuations, and corrosive environments without compromising its structural integrity.Additionally, the pipe's versatility allows it to be used across multiple industries, including construction, aerospace, automotive, and marine sectors. It can be employed for applications such as HVAC systems, fluid transmission, structural support, and more. The adaptability of the 7-inch aluminum pipe makes it a valuable asset for a wide range of projects, providing a cost-effective solution for many different requirements.Innovative Design and Precision Engineering:Company XYZ has implemented advanced manufacturing processes and precision engineering techniques to create the 7-inch aluminum pipe. The seamless construction ensures uniformity throughout the entire length of the pipe, eliminating weak points and enhancing overall performance.Furthermore, the incorporation of an innovative internal ribbing system enhances the pipe's structural integrity, effectively reducing any potential risks associated with external loading or stress. This design feature not only strengthens the pipe but also enables it to withstand higher pressure fluids, making it suitable for applications requiring optimal performance.Environmental Sustainability:Company XYZ acknowledges the critical importance of environmental sustainability in today's world. As a result, their 7-inch aluminum pipe is manufactured using recycled aluminum, minimizing the demand for raw materials and reducing the carbon footprint. This commitment to eco-friendly practices showcases the company's dedication to building a greener future while still delivering excellent products.Quality Assurance and Compliance:To ensure the utmost quality, Company XYZ rigorously tests the 7-inch aluminum pipe at every stage of its production cycle. Strict quality control measures are implemented to adhere to national and international standards, ensuring that each pipe meets industry regulations and specifications. This dedication to quality assurance guarantees the reliability and safety of the product, providing customers with peace of mind.Industry Implications:The introduction of the 7-inch aluminum pipe by Company XYZ is anticipated to bring significant changes to multiple industries:1. Construction Industry: The exceptional strength and durability of the pipe make it a perfect fit for structural applications, such as framework and support systems, where reliability is crucial.2. Aerospace Industry: The lightweight nature and high corrosion resistance of the aluminum pipe make it an ideal component for aircraft manufacturing, improving fuel efficiency, and reducing maintenance costs.3. Automotive Industry: The ability to withstand extreme temperatures and corrosive environments makes the 7-inch aluminum pipe suitable for exhaust systems and fluid transmission, enhancing the overall performance and longevity of vehicles.4. Marine Industry: With its superior resistance to saltwater corrosion, the aluminum pipe becomes an excellent choice for various marine applications, including shipbuilding, offshore structures, and desalination plants.In conclusion, Company XYZ's launch of the groundbreaking 7-inch aluminum pipe is set to revolutionize the industry, offering unparalleled strength, versatility, and environmental sustainability. The company's commitment to delivering high-quality products through innovation and precision engineering has positioned them at the forefront of the market. As various industries embrace this game-changing product, its positive impact is expected to resonate across numerous sectors, redefining standards and driving further advancements in the use of aluminum pipes.

Discover the Incredible Strength of Aluminum Angle for Various Applications

Title: Aluminum Angle Strength: Revolutionizing Structural Integrity in the Construction IndustryIntroduction:In the thriving construction industry, innovation and advancements in material sciences continue to pave the way for groundbreaking developments. One such milestone comes in the form of Aluminum Angle Strength, an exceptional product that is all set to revolutionize structural integrity within the sector. Developed by a leading industry player, this groundbreaking solution ensures unparalleled strength, durability, and flexibility in construction projects, promising to transform the way we build our cities.Paragraph 1:Aluminum Angle Strength, unlike conventional building materials, offers an array of advantages that cater to the needs of the modern construction industry. Derived from high-grade aluminum alloys, this material boasts a remarkable strength-to-weight ratio, enabling architects and engineers to design and construct buildings that are both structurally robust and aesthetically pleasing.Paragraph 2:The versatility of Aluminum Angle Strength sets it apart from traditional materials. Whether it's skyscrapers, bridges, or commercial complexes, this product offers unparalleled flexibility, making it suitable for a wide range of applications. Its adaptability allows for intricate architectural designs, reducing limitations and fueling the imagination of builders worldwide.Paragraph 3:In addition to its impressive strength, Aluminum Angle Strength delivers exceptional durability, capable of withstanding diverse weather conditions and natural disasters. Its resistance to corrosion and rust ensures that structures built using this material will maintain their integrity and longevity, considerably reducing maintenance and repair costs over time.Paragraph 4:With an increased focus on sustainable building practices, aluminum plays a pivotal role as an environmentally friendly material. By choosing Aluminum Angle Strength over conventional alternatives, construction companies contribute to energy conservation and reduced carbon footprints. Aluminum is highly recyclable, ensuring minimal waste during production, and can be easily recycled at the end of a building's lifespan, reducing the impact on the environment.Paragraph 5:For construction companies, the adoption of Aluminum Angle Strength presents a multitude of advantages. By utilizing this lightweight material, transportation costs are significantly reduced, resulting in more economical construction projects. Furthermore, its ease of installation enhances construction speed, allowing for faster project completion and reduced labor expenses.Paragraph 6:This groundbreaking product has already found widespread acclaim in multiple construction projects around the world. Notable examples include the construction of state-of-the-art skyscrapers, offshore wind turbines, and intricate architectural wonders. The successful application of Aluminum Angle Strength in these projects has solidified its standing within the industry and garnered trust among builders, architects, and engineers.Paragraph 7:As the demand for more sustainable, cost-effective, and durable construction materials continues to grow, Aluminum Angle Strength stands firmly at the forefront of these requirements. Its application extends to various sectors, including residential, commercial, and infrastructure, making it the logical choice for construction companies across the globe.Conclusion:Aluminum Angle Strength is a game-changer in the construction industry, offering a unique combination of strength, durability, and flexibility. With its versatility, sustainability, and cost-effectiveness, this cutting-edge material is poised to redefine the way we design and construct structures worldwide. Embracing Aluminum Angle Strength will undoubtedly elevate the standards of structural integrity and sustainability, making it an invaluable asset in shaping the cities of tomorrow.

The Strength of Aluminium Tubes: Unveiling Impressive Performance

Article:In recent years, the aluminium tube market has witnessed an unprecedented surge in demand, driven largely by the growth of the packaging industry. The lightweight and durable qualities of aluminium tubes make them ideal for use in a wide variety of applications, ranging from cosmetics and pharmaceuticals to food and beverage packaging.But as the demand for aluminium tubes has increased, so too has the demand for high-quality, strong, and reliable tubes. And that's where Aluminium Tube Strength comes into play. A leading manufacturer of aluminium tubes, Aluminium Tube Strength is renowned for its commitment to producing the finest quality tubes on the market.Founded in 1995, Aluminium Tube Strength has grown to become one of the most respected and trusted names in the industry. The company's success is due in large part to its unwavering dedication to quality and innovation. Using the latest technology and manufacturing processes, Aluminium Tube Strength is able to produce tubes that not only meet but exceed the expectations of its customers.One of the company's most impressive innovations is its patented manufacturing process, which enables it to produce tubes with unmatched strength and durability. Unlike traditional manufacturing methods, which can lead to weak spots and uneven thicknesses in the walls of the tube, Aluminium Tube Strength's process ensures that each tube is perfectly smooth and uniform in strength.This attention to quality has not gone unnoticed. Over the years, Aluminium Tube Strength has won numerous awards for its commitment to excellence, including the prestigious National Quality Award. But for the company's founder and CEO, Mr. Smith, the real reward is in knowing that the company's products are making a difference in the lives of people around the world."Every day, we receive letters and emails from customers who have used our tubes to package their products," says Mr. Smith. "They tell us how our tubes have helped them to grow their businesses, reach new markets, and improve their bottom line. And that's really what we're all about."But for Aluminium Tube Strength, success is not just about producing high-quality products. The company is also committed to sustainability and social responsibility. It has implemented a number of initiatives to reduce its carbon footprint and promote eco-friendly practices in its operations. It also supports a range of social causes, including education and healthcare initiatives in the communities where it operates.Looking ahead, Aluminium Tube Strength is focused on continuing to innovate and improve its products, while maintaining its commitment to quality and sustainability. With the global demand for aluminium tubes showing no signs of slowing down, the company is well-positioned to meet the evolving needs of its customers and the market as a whole."We have a strong foundation built on quality, innovation, and social responsibility," says Mr. Smith. "We are confident that we can continue to grow and thrive in this exciting and dynamic industry."In conclusion, Aluminium Tube Strength is a company that has built a reputation for excellence in the aluminium tube market. Its commitment to quality, innovation, and social responsibility has earned it the trust and loyalty of customers around the world. With its patented manufacturing process and focus on sustainability, the company is poised to continue leading the industry well into the future.