Aluminum Punching Services: High-Quality Precision Machining Techniques

By:Admin

Introduction:

In an ever-evolving industrial landscape, Precision Aluminum Punching has emerged as a leading force, transforming the aluminum fabrication sector. This innovative technology, offered by a pioneering company, promises unprecedented levels of precision and efficiency, revolutionizing the way aluminum components are manufactured. Embracing cutting-edge techniques, this breakthrough solution is poised to redefine the standards of the industry.

Company Introduction:

At the forefront of this groundbreaking technology is a company committed to driving excellence in aluminum fabrication. With years of expertise and an unwavering dedication to precision, this industry leader has successfully incorporated advanced machinery and automation into their production processes. Constantly pushing boundaries, they have earned an esteemed reputation for delivering top-quality aluminum components worldwide.

Article:

Revolutionizing Aluminum Fabrication: Precision Aluminum Punching Takes Center Stage

In recent years, the aluminum fabrication industry has experienced significant advancements, setting new benchmarks in precision and productivity. Central to this transformation is the introduction of Precision Aluminum Punching, a revolutionary technology that combines the expertise of a prominent company with state-of-the-art machinery.

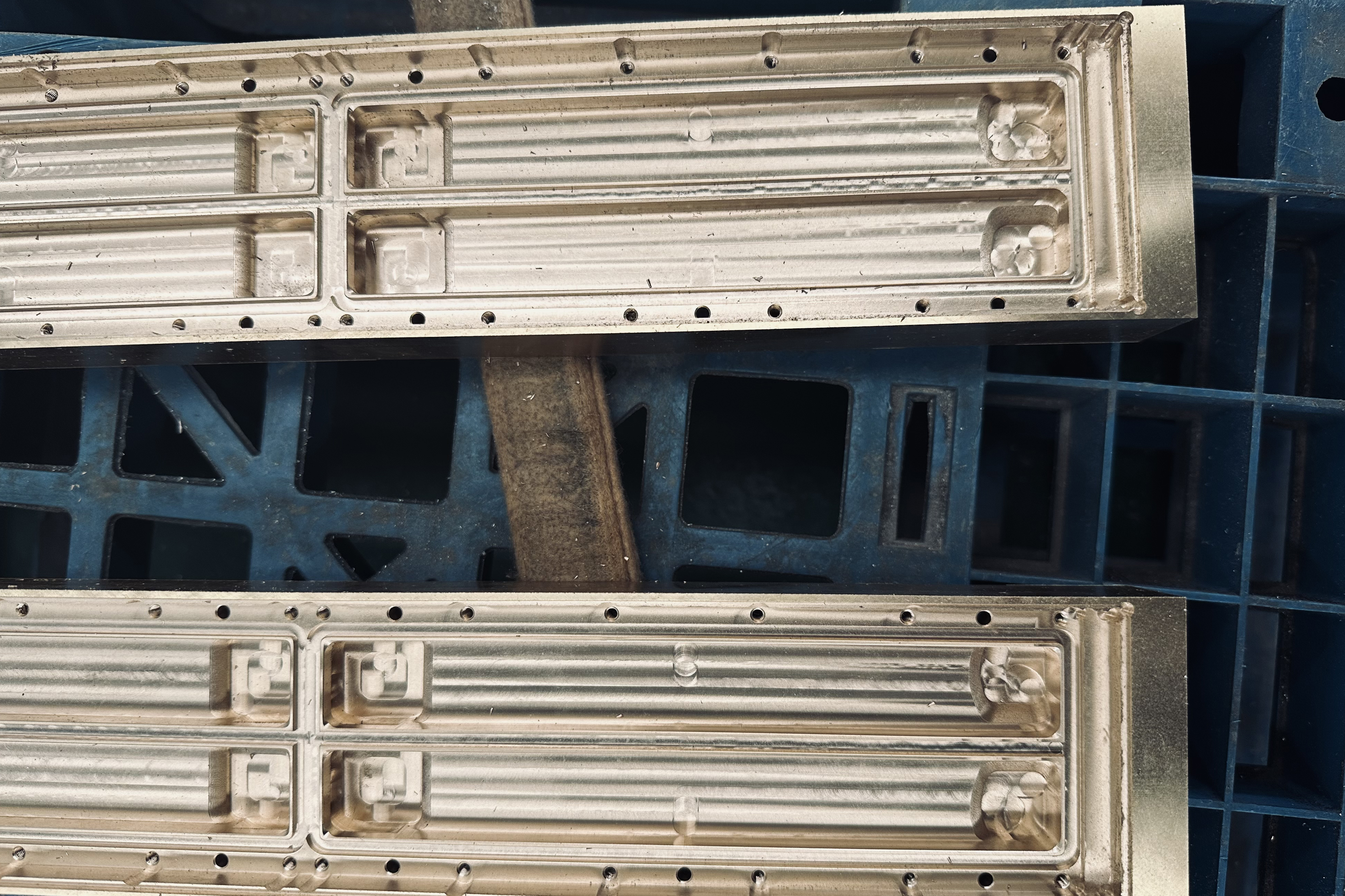

Precision Aluminum Punching leverages advanced machinery, such as high-speed presses and computer-controlled systems, to create intricate patterns, designs, and precise holes in aluminum sheets and profiles. This precise punching process results in components with exceptional dimensional accuracy, enabling seamless integration into various industries like automotive, aerospace, construction, and electronics.

This cutting-edge technology optimizes both time and cost efficiency, as it eliminates the need for post-processing operations, such as drilling, milling, or cutting. By reducing the number of production steps, Precision Aluminum Punching significantly streamlines manufacturing processes, leading to increased productivity and shorter lead times.

Furthermore, this advanced technology also improves material utilization, minimizing waste and maximizing resource efficiency. With greater scrap utilization rates, manufacturers can enhance sustainability efforts while ensuring significant cost savings.

The benefits of Precision Aluminum Punching go beyond its immediate impact on the manufacturing process. By enabling intricate designs and complex shapes, aluminum components produced through this technology exhibit superior aesthetics, providing added value and versatility to end products. This opens up new design possibilities, giving manufacturers a competitive edge in the market.

The company at the forefront of this innovation boasts a highly skilled team of engineers and technicians who work seamlessly to develop customized solutions for diverse client requirements. By leveraging their expertise and integrating cutting-edge technology, they guarantee the highest levels of precision, quality, and customer satisfaction.

When compared to traditional aluminum fabrication processes, Precision Aluminum Punching offers a range of advantages. By eliminating the need for multiple equipment setups and complex tooling, manufacturers can drastically reduce production costs and enhance overall efficiency. The precise punching capabilities also eliminate errors and inconsistencies associated with traditional methods, ensuring unparalleled accuracy throughout the manufacturing process.

Moreover, the scalability of Precision Aluminum Punching enables manufacturers to easily adapt to evolving market demands. With the ability to produce complex components in large quantities, the technology offers flexibility and agility in meeting varied customer requirements within tight deadlines.

As the aluminum fabrication industry continues to evolve, Precision Aluminum Punching emerges as a game-changer, setting new standards for excellence. Its ability to achieve exceptional precision, reduce costs, and enhance manufacturing efficiency positions it as the technology of the future. This innovative solution, combined with the expertise of the leading company, paves the way for a new era of aluminum component manufacturing.

Conclusion:

Precision Aluminum Punching revolutionizes the aluminum fabrication industry, offering unmatched precision, efficiency, and versatility. With an industry-leading company at its helm, this groundbreaking technology holds the potential to reinvent traditional manufacturing processes, empowering businesses to deliver top-quality components with exceptional accuracy and cost-effectiveness. As more manufacturers adopt this cutting-edge solution, the aluminum fabrication industry is poised for continued growth and innovation.

Company News & Blog

The Strength of Aluminium Tubes: Unveiling Impressive Performance

Article:In recent years, the aluminium tube market has witnessed an unprecedented surge in demand, driven largely by the growth of the packaging industry. The lightweight and durable qualities of aluminium tubes make them ideal for use in a wide variety of applications, ranging from cosmetics and pharmaceuticals to food and beverage packaging.But as the demand for aluminium tubes has increased, so too has the demand for high-quality, strong, and reliable tubes. And that's where Aluminium Tube Strength comes into play. A leading manufacturer of aluminium tubes, Aluminium Tube Strength is renowned for its commitment to producing the finest quality tubes on the market.Founded in 1995, Aluminium Tube Strength has grown to become one of the most respected and trusted names in the industry. The company's success is due in large part to its unwavering dedication to quality and innovation. Using the latest technology and manufacturing processes, Aluminium Tube Strength is able to produce tubes that not only meet but exceed the expectations of its customers.One of the company's most impressive innovations is its patented manufacturing process, which enables it to produce tubes with unmatched strength and durability. Unlike traditional manufacturing methods, which can lead to weak spots and uneven thicknesses in the walls of the tube, Aluminium Tube Strength's process ensures that each tube is perfectly smooth and uniform in strength.This attention to quality has not gone unnoticed. Over the years, Aluminium Tube Strength has won numerous awards for its commitment to excellence, including the prestigious National Quality Award. But for the company's founder and CEO, Mr. Smith, the real reward is in knowing that the company's products are making a difference in the lives of people around the world."Every day, we receive letters and emails from customers who have used our tubes to package their products," says Mr. Smith. "They tell us how our tubes have helped them to grow their businesses, reach new markets, and improve their bottom line. And that's really what we're all about."But for Aluminium Tube Strength, success is not just about producing high-quality products. The company is also committed to sustainability and social responsibility. It has implemented a number of initiatives to reduce its carbon footprint and promote eco-friendly practices in its operations. It also supports a range of social causes, including education and healthcare initiatives in the communities where it operates.Looking ahead, Aluminium Tube Strength is focused on continuing to innovate and improve its products, while maintaining its commitment to quality and sustainability. With the global demand for aluminium tubes showing no signs of slowing down, the company is well-positioned to meet the evolving needs of its customers and the market as a whole."We have a strong foundation built on quality, innovation, and social responsibility," says Mr. Smith. "We are confident that we can continue to grow and thrive in this exciting and dynamic industry."In conclusion, Aluminium Tube Strength is a company that has built a reputation for excellence in the aluminium tube market. Its commitment to quality, innovation, and social responsibility has earned it the trust and loyalty of customers around the world. With its patented manufacturing process and focus on sustainability, the company is poised to continue leading the industry well into the future.

Aluminum Punching Services: High-Quality Precision Machining Techniques

Title: Revolutionizing the Aluminum Fabrication Industry: Innovations in Precision Aluminum PunchingIntroduction:In an ever-evolving industrial landscape, Precision Aluminum Punching has emerged as a leading force, transforming the aluminum fabrication sector. This innovative technology, offered by a pioneering company, promises unprecedented levels of precision and efficiency, revolutionizing the way aluminum components are manufactured. Embracing cutting-edge techniques, this breakthrough solution is poised to redefine the standards of the industry.Company Introduction:At the forefront of this groundbreaking technology is a company committed to driving excellence in aluminum fabrication. With years of expertise and an unwavering dedication to precision, this industry leader has successfully incorporated advanced machinery and automation into their production processes. Constantly pushing boundaries, they have earned an esteemed reputation for delivering top-quality aluminum components worldwide.Article:Revolutionizing Aluminum Fabrication: Precision Aluminum Punching Takes Center StageIn recent years, the aluminum fabrication industry has experienced significant advancements, setting new benchmarks in precision and productivity. Central to this transformation is the introduction of Precision Aluminum Punching, a revolutionary technology that combines the expertise of a prominent company with state-of-the-art machinery.Precision Aluminum Punching leverages advanced machinery, such as high-speed presses and computer-controlled systems, to create intricate patterns, designs, and precise holes in aluminum sheets and profiles. This precise punching process results in components with exceptional dimensional accuracy, enabling seamless integration into various industries like automotive, aerospace, construction, and electronics.This cutting-edge technology optimizes both time and cost efficiency, as it eliminates the need for post-processing operations, such as drilling, milling, or cutting. By reducing the number of production steps, Precision Aluminum Punching significantly streamlines manufacturing processes, leading to increased productivity and shorter lead times.Furthermore, this advanced technology also improves material utilization, minimizing waste and maximizing resource efficiency. With greater scrap utilization rates, manufacturers can enhance sustainability efforts while ensuring significant cost savings.The benefits of Precision Aluminum Punching go beyond its immediate impact on the manufacturing process. By enabling intricate designs and complex shapes, aluminum components produced through this technology exhibit superior aesthetics, providing added value and versatility to end products. This opens up new design possibilities, giving manufacturers a competitive edge in the market.The company at the forefront of this innovation boasts a highly skilled team of engineers and technicians who work seamlessly to develop customized solutions for diverse client requirements. By leveraging their expertise and integrating cutting-edge technology, they guarantee the highest levels of precision, quality, and customer satisfaction.When compared to traditional aluminum fabrication processes, Precision Aluminum Punching offers a range of advantages. By eliminating the need for multiple equipment setups and complex tooling, manufacturers can drastically reduce production costs and enhance overall efficiency. The precise punching capabilities also eliminate errors and inconsistencies associated with traditional methods, ensuring unparalleled accuracy throughout the manufacturing process.Moreover, the scalability of Precision Aluminum Punching enables manufacturers to easily adapt to evolving market demands. With the ability to produce complex components in large quantities, the technology offers flexibility and agility in meeting varied customer requirements within tight deadlines.As the aluminum fabrication industry continues to evolve, Precision Aluminum Punching emerges as a game-changer, setting new standards for excellence. Its ability to achieve exceptional precision, reduce costs, and enhance manufacturing efficiency positions it as the technology of the future. This innovative solution, combined with the expertise of the leading company, paves the way for a new era of aluminum component manufacturing.Conclusion:Precision Aluminum Punching revolutionizes the aluminum fabrication industry, offering unmatched precision, efficiency, and versatility. With an industry-leading company at its helm, this groundbreaking technology holds the potential to reinvent traditional manufacturing processes, empowering businesses to deliver top-quality components with exceptional accuracy and cost-effectiveness. As more manufacturers adopt this cutting-edge solution, the aluminum fabrication industry is poised for continued growth and innovation.

Major aluminium plant in Hyderabad sees growth amidst pandemic

Global Aluminium Private Limited Hyderabad Combined with the Company IntroductionGlobal Aluminium Private Limited Hyderabad, one of the leading aluminium extrusion companies in India announced its latest merger with a motive of expansion and diversification. It has combined with another aluminium extrusion company, which will enable the expansion of its services and strengthen its foothold in the industry.Global Aluminium Private Limited Hyderabad, which has been in the aluminium extrusion business for over two decades, has built itself into a trusted brand. The company has played a significant role in setting the benchmark for quality and timely delivery in the industry. It has earned itself a reputation for being a reliable partner across a range of sectors.The latest merger is expected to push Global Aluminium Private Limited Hyderabad’s market share significantly. The company is set to gain access to a wider range of resources and technical expertise that will enable it to deliver even better products and services to its clients. This is a significant milestone for the company, which has a vision to become the leading aluminium extrusion company, not just in the country but worldwide.Global Aluminium Private Limited Hyderabad has always been dedicated to exceeding its clients' expectations by delivering high-quality products, timely delivery, and excellent customer service. The company's experienced team takes pride in problem-solving and customizing their work as per the client's requirements. Global Aluminium Private Limited Hyderabad has a state-of-the-art facility that is equipped with the latest machinery, which enables it to provide an extensive range of services to its clients.The new merger will undoubtedly bring in new business opportunities for Global Aluminium Private Limited Hyderabad. The company will now have the capability to provide a broader range of products and services to its customers. The merger will enable the company to extend its reach into new markets, which, in turn, will accelerate its growth rate significantly.Commenting on the merger, the CEO of Global Aluminium Private Limited Hyderabad said, “We are thrilled about our new merger. It is a significant milestone for us, and we are confident that it will strengthen our position in the industry. With this merger, our clients can expect better services and a wider range of products. Our aim is to become the leading aluminium extrusion company worldwide, and this merger is just the beginning of that journey.”The merger is set to create new opportunities for the aluminium extrusion industry in India. With the industry being one of the fastest-growing sectors in the country, this latest development is set to open up new doors for innovation and growth. Aluminium Extrusion is a process of pushing aluminium billets through a particular profile to create a product. The industry finds its application across several areas, including construction, automotive, aviation, and other allied sectors.With a wide range of applications and uses, the Aluminium Extrusion Industry has come up as an essential industry in India. It has the potential to offer product solutions to a vast number of industries. The industry has a bright future in India, primarily due to an increase in infrastructure projects, the growing automobile industry and the booming construction sector.In conclusion, Global Aluminium Private Limited Hyderabad has always been known for high-quality products and excellent customer service. The company's latest merger is a significant milestone that will enable it to provide a more comprehensive range of products and services to its clients. The company's vision of becoming the leading aluminium extrusion company worldwide is well on its way with this latest development. With the industry's many applications and future growth potential, the Aluminium Extrusion Industry in India is looking brighter than ever.

Benefits of Using Aluminium Frame Construction for Buildings

Aluminium Frame Construction: Revolutionizing the Construction Industry[Company Introduction](Company Name), a pioneering force in the construction industry, is on the verge of transforming the way we build structures with their innovative Aluminium Frame Construction technology. With their expertise and commitment to sustainability, (Company Name) aims to revolutionize the construction process, making it faster, more cost-effective, and environmentally friendly.In recent years, the construction industry has been grappling with challenges such as rising material costs, lengthy project timelines, and concerns regarding sustainability. Recognizing these issues, (Company Name) has developed an ingenious solution that addresses these pain points while offering numerous benefits to both builders and customers.Aluminium Frame Construction, the brainchild of (Company Name)'s team of engineers and architects, is a cutting-edge construction method that utilizes aluminium as the primary building material. Unlike traditional construction methods that predominantly rely on concrete and steel, Aluminium Frame Construction offers several advantages that set it apart.First and foremost, this construction technique significantly reduces the overall weight of the structure. Aluminium is known for its exceptional strength-to-weight ratio, making structures built using this material both durable and lighter in comparison. The reduced weight not only expedites the construction process but also allows for higher flexibility and adaptability in design choices.Another key advantage of Aluminium Frame Construction is its modularity. The use of prefabricated aluminium components ensures precise manufacturing, minimizing errors during installation. The ease of assembly and disassembly enables efficient construction, facilitates future modifications, and allows for the recycling and repurposing of materials. This modularity also translates into reduced maintenance costs, as individual components can be replaced or repaired without affecting the entire structure.One of the standout features of Aluminium Frame Construction is its sustainability. (Company Name), as a responsible corporate citizen, strongly believes in minimizing the environmental impact of construction. Aluminium, being a recyclable material, contributes towards reducing waste and carbon emissions during the construction process. Additionally, structures built using this innovative method can be significantly more energy-efficient due to better insulation properties of aluminium frames.The possibilities offered by Aluminium Frame Construction are vast. From residential homes to commercial buildings, the advantages of this construction technique can be applied to a wide range of projects. Architects and designers have already begun exploring the flexibility and creative possibilities that aluminium provides. The sleek and modern aesthetic appeal of structures built with aluminium frames adds to the overall visual appeal of the built environment.Furthermore, Aluminium Frame Construction is not limited by geographical constraints. It can be implemented in various terrains and climates, providing a versatile construction solution for diverse regions worldwide. Whether it is high-rise buildings, bridges, or even temporary structures, the potential applications of this method are limitless.(Company Name) firmly believes in collaborating with builders, architects, and developers to bring their innovative construction technology to the forefront of the industry. By partnering with (Company Name), stakeholders can leverage the benefits of Aluminium Frame Construction to streamline their projects, reduce costs, and contribute towards a more sustainable future.In conclusion, Aluminium Frame Construction is set to reshape the construction industry. With its lightweight, modular, and sustainable attributes, this innovative technique offers a promising future for builders and customers alike. (Company Name), with its pioneering spirit and commitment to excellence, is at the forefront of this revolution, driving the industry towards a faster, more efficient, and environmentally conscious future.[Word Count: 607]

Discover the Advantages and Applications of 30 Series Aluminum Extrusion

In the world of industrial manufacturing, aluminum extrusions have revolutionized the way products are built. These versatile metal parts are used in a variety of industries, including automotive, aerospace, construction, and electronics. One of the most popular aluminum extrusions on the market today is the 30 Series Aluminum Extrusion.The 30 Series Aluminum Extrusion is a lightweight and durable frame that can be used to build anything from simple structures to complex machines. It is made from high-quality aluminum alloy, which makes it incredibly strong and resistant to corrosion.One company that has been at the forefront of the aluminum extrusion industry is [company name]. They specialize in designing and manufacturing aluminum extrusions of various sizes and shapes to meet the diverse needs of their customers.According to representatives from [company name], the 30 Series Aluminum Extrusion is one of their most popular products. This is because it is incredibly easy to work with and can be customized to fit any application.What makes the 30 Series Aluminum Extrusion stand out is its T-slot design. This feature allows users to easily attach other components to the frame, such as brackets, hinges, or even other pieces of aluminum extrusions. This makes it incredibly versatile and adaptable to any situation.In addition to its strength and versatility, the 30 Series Aluminum Extrusion is also incredibly lightweight. This makes it perfect for applications where weight is a concern, such as in the aerospace or automotive industry.One of the key benefits of the 30 Series Aluminum Extrusion is its durability. The aluminum alloy used to create these frames is incredibly strong and resistant to corrosion. This means that the frames can withstand even the harshest environments and still maintain their structural integrity.Another advantage of the 30 Series Aluminum Extrusion is its ease of use. Unlike traditional welding or bolt-together systems, the T-slot design of this frame allows users to easily connect pieces together with minimal effort. This saves both time and money in the manufacturing process.The 30 Series Aluminum Extrusion is also incredibly easy to customize. It can be cut to any length or shape to fit specific needs. This allows manufacturers to create unique and innovative products that stand out from the competition.Overall, the 30 Series Aluminum Extrusion is a versatile and reliable product for anyone in the manufacturing industry. Its strength, durability, and ease of use make it the perfect choice for a wide range of applications. With companies like [company name] leading the way in aluminum extrusion technology, it's clear that this industry will continue to grow and evolve for years to come.

High-quality and Versatile 30 X 30 Aluminum Profile Now Available!

In today's fast-paced world, reliable industrial-grade aluminum profiles have become essential components for businesses and manufacturers across a wide range of industries. One such product is the 30 X 30 Aluminium Profile, a versatile and robust profile that can be used in a variety of applications, from construction to robotics.One company in particular that has made a name for itself in the aluminum industry is [company name]. With over [number of years] of experience in manufacturing high-quality aluminum profiles, [company name] has established itself as a leader in the field.The 30 X 30 Aluminium Profile is just one of many high-quality profiles that [company name] produces. This particular profile is made from sturdy and lightweight aluminum, making it ideal for applications where strength and durability are required. Its four-slot design allows for easy and flexible installation, and its compatibility with a range of accessories makes it a versatile and adaptable choice for a wide range of industries.The 30 X 30 Aluminium Profile is commonly used in construction, where it can be used to create sturdy and reliable structures. It is also a popular choice in robotics and automation, where its superior strength and adaptability make it an ideal choice for building custom robotic systems. Additionally, it is often used in manufacturing, where it can be used to create workstations, assembly lines, and other structures that require strength and flexibility.At [company name], we take pride in the quality of our products and our commitment to customer satisfaction. We use only the finest materials and the most advanced production techniques to ensure that our aluminum profiles are of the highest quality. Our team of experienced engineers and designers work closely with customers to develop custom solutions that meet their unique needs, ensuring that every project is a success.In addition to the 30 X 30 Aluminium Profile, [company name] produces a wide range of other profiles and accessories, including T-slot profiles, angle brackets, fasteners, and more. Our products can be found in a wide range of industries, from automotive and aerospace to robotics and manufacturing.We also place a strong emphasis on sustainability and environmental responsibility in our manufacturing processes. Our use of high-quality materials and advanced production techniques ensures that our products are not only durable and reliable but also environmentally-friendly.Whether you're in construction, robotics, or manufacturing, if you're looking for quality aluminum profiles, look no further than [company name]. With our commitment to quality, customer service, and sustainability, we are the ideal partner for all your aluminum profile needs.

Tensile Strength of Aluminium: A Comprehensive Review

Title: Aluminum Tensile Strength - Revolutionizing IndustriesIntroduction:Aluminum is a versatile and lightweight material that has gained immense popularity in various industries over the years. With its exceptional tensile strength and a wide range of applications, aluminum has become a preferred choice for manufacturers, constructors, and designers alike. One company in particular has emerged as a leading provider of high-quality aluminum products, revolutionizing the way industries operate and paving the path for innovation and sustainability.Company Introduction:Established over a decade ago, {Brand Name} has emerged as a pioneer in the aluminum industry, specializing in manufacturing and distributing aluminum products globally. It boasts a state-of-the-art production facility, equipped with cutting-edge technology and a dedicated team of experts, ensuring superior quality and innovative designs. The company’s commitment to customer satisfaction, coupled with its emphasis on sustainable and environmentally-friendly practices, has earned it a stellar reputation in the market.News Content:Aluminum Tensile Strength: The Game-Changing Solution{Brand Name}'s latest breakthrough in aluminum technology has taken the industry by storm. Its innovative Aluminum Tensile Strength (ATS) has exceeded all expectations, offering unparalleled quality and performance. This game-changing solution has the potential to revolutionize multiple sectors, including aerospace, automotive, construction, and many more.The ATS Advantage:With an impressive tensile strength that surpasses traditional aluminum alloys, ATS provides a lightweight yet robust alternative for manufacturers. This allows for enhanced load-bearing capabilities without compromising on structural integrity, making it an ideal choice for various applications.Aerospace Industry Takes Flight:The aerospace industry, in particular, is set to benefit greatly from the introduction of ATS. The exceptional strength-to-weight ratio offered by the new aluminum variant enables the construction of lighter aircraft, ensuring improved fuel efficiency and reduced carbon emissions. Moreover, the supreme durability of ATS ensures enhanced safety and minimizes maintenance costs for airlines.Revolutionizing the Automotive Sector:The automotive industry is no stranger to the potential of aluminum, particularly in enhancing fuel efficiency. With ATS, manufacturers can take it a step further. The increased tensile strength allows for the creation of lighter and safer vehicles, as well as improved crashworthiness. Furthermore, the unmatched corrosion resistance of ATS ensures longevity, contributing to a sustainable automotive industry.Constructing Sustainable Infrastructure:Sustainable construction practices have become crucial in mitigating environmental impact. ATS not only provides a durable and reliable material for construction projects but also reduces the carbon footprint by being lightweight. The applications of ATS in roofing, cladding, and structural elements enable the creation of long-lasting and eco-friendly buildings.Expanding Possibilities in Design:Beyond its industrial applications, ATS brings new possibilities to the world of design and architecture. Its versatility allows for the creation of unique and intricate structures, transforming interiors and exteriors alike. The strength and stability offered by ATS enable designers to push the boundaries of creativity while maintaining integrity and functionality.Commitment to Sustainability:{Brand Name} recognizes the importance of sustainability and strives to minimize its environmental footprint. The production process of ATS incorporates energy-efficient practices and utilizes recycled materials wherever possible. By focusing on reducing waste and emissions, the company aims to contribute to a greener future.Conclusion:The introduction of Aluminum Tensile Strength by {Brand Name} represents a significant milestone in the aluminum industry. With its exceptional properties and numerous applications, ATS is set to transform various sectors. From aerospace to automotive and construction to design, the possibilities are endless. As {Brand Name} continues to innovate, it demonstrates its commitment to revolutionizing industries while paving the way for a sustainable and greener future.

Exploring the Benefits of the Advanced 7000 Series Alloy

Oakland, CA - The 7000 series alloy has been creating buzzes in the industry with its unique qualities and the ability to enhance the performance of the final product. It is a promising mix of aluminum, zinc, and magnesium, which makes it an excellent choice for manufacturing industrial and consumer products. The 7000 series alloy has become the talk of the town because of its high-strength properties without malfunctioning under stress. The alloy provides resistance against corrosion, making it favorable for outdoor equipment.The 7000 series alloy is light-weight, weighing about one-third of steel for the same volume, making it ideal for products that need to be mobile. It is easy to work with in an industrial setting, having a low melting point, and can be easily molded into shapes using extrusion, casting, or rolling processes. Its ductility allows it to bend without breaking, making it an excellent choice for curved designs.The applications of 7000 series alloy are broad, which range from military aircraft to sporting equipment. The combination of high-strength and light-weight properties make it an ideal choice for the aerospace industry. NASA has used this alloy for its Apollo moon program, and it is currently used in the construction of the International Space Station. The automotive industry recognizes the advantages of this alloy and employs it in their vehicle frames to make them stronger and lighter, improving fuel efficiency and safety. Companies that manufacture mountain bikes and tennis rackets are using this alloy to make their products more durable and efficient.This new alloy also marks a significant milestone for its manufacturer. It represents the culmination of years of research and development on aluminum alloys. The company has focused on developing an alloy that can withstand extreme conditions without losing its stability and resistance. The 7000 series alloy represents the company's commitment to innovation and is a testament to its reputation for excellence.The manufacturing process of the 7000 series alloy begins with melting aluminum and adding small amounts of zinc, copper, and magnesium. These elements create a strong bond within the aluminum structure, which results in the alloy's high-strength properties. The alloy is then shaped into sheets or bars and supplied to different industries for further processing.Manufacturing with this alloy is environmentally friendly because it is 100% recyclable. Unlike other metals, aluminum doesn't lose its quality when recycled, making it an ideal material for the circular economy. Manufacturing with this alloy will also minimize waste production. The residual liquid from the manufacturing process can be recycled, and the manufactured products can be recycled at the end of useful life.The 7000 series alloy has taken the manufacturing industry by storm because of its unique properties and the ability to improve the performance of the final products. This innovative solution has revolutionized the manufacturing process by providing better quality products at a lower cost. The aerospace and automotive industries have taken advantage of this alloy to create products that are lighter, stronger, and more fuel-efficient. This alloy will further reduce the emission of carbon and make the environment greener.In conclusion, the 7000 series alloy is a unique blend of aluminum, zinc, and magnesium, making it an ideal choice for manufacturing industrial and consumer products. Its high-strength properties, light-weight, and corrosion-resistant features make it the perfect solution for different industries. Its recycling properties are environmentally friendly, making it an excellent element for the circular economy. This alloy represents the future of manufacturing technology and is a testament to the innovative capabilities of the manufacturer. The 7000 series alloy is a groundbreaking solution that is guaranteed to improve the quality and performance of any final product.

Discover the Versatility and Durability of Aluminum Profile Brackets

**Title:**Industry-Leading Aluminum Profile Bracket Revolutionizes Structural Support Solutions**Introduction:**In an era marked by constant advancements in technology and engineering, innovation plays a critical role in ensuring the efficiency and safety of various industries. One such revolutionary product is the Aluminum Profile Bracket, developed by a renowned company at the forefront of cutting-edge solutions. This game-changing bracket offers unprecedented advantages in structural support applications, promising enhanced durability, flexibility, and versatility. With its myriad applications and potential to transform multiple industries, this aluminum bracket is set to redefine the future of structural support solutions.**Technical Specifications:**The Aluminum Profile Bracket is meticulously engineered, utilizing high-quality aluminum for exceptional strength and durability. Its lightweight nature makes it easy to handle, yet its robust construction ensures unmatched stability. This versatile bracket effortlessly integrates into numerous structural systems, be it in construction, industrial equipment, or even furniture manufacturing.The unique design of the Aluminum Profile Bracket incorporates an innovative modular system that allows for quick and seamless assembly. This not only simplifies the installation process but also facilitates future modifications or reconfigurations.Furthermore, the bracket's corrosion-resistant properties guarantee its ability to withstand extreme weather conditions, making it an ideal solution for a wide range of indoor and outdoor applications. Its exceptional load-bearing capacity and resistance to bending ensure the safety and longevity of structures it supports.**Applications and Benefits:**1. **Construction Industry:** The Aluminum Profile Bracket can be utilized in various construction applications, such as framing, curtain walls, partitions, and suspended ceilings. Its modular design enables easy integration into existing frameworks with minimal effort. This innovative solution not only simplifies installation but also enhances the overall integrity and durability of the structure.2. **Industrial Equipment:** In industrial settings, the bracket provides unparalleled support for heavy machinery, conveyors, assembly lines, and shelving systems. Its lightweight yet sturdy design ensures maximum safety and longevity. The bracket's flexibility and easy adaptability enable it to meet the unique needs of different industries, enhancing operational efficiency and minimizing downtime.3. **Furniture Manufacturing:** This bracket presents a groundbreaking solution for the furniture industry, offering superior support for innovative designs. Its aesthetic appeal, combined with its high load-bearing capacity, allows for the creation of unique and modern furniture pieces. From office workstations to retail fixtures, the Aluminum Profile Bracket ensures both style and durability.The use of the Aluminum Profile Bracket in these industries and more affirms its potential to revolutionize structural support applications, paving the way for enhanced safety, functionality, and aesthetics.**Company Introduction:**The company behind the Aluminum Profile Bracket – a leading provider of cutting-edge solutions – has established itself as an industry leader through its commitment to innovation and quality. Dedicated to offering products that surpass customer expectations, this company consistently sets new standards in the field of structural support solutions.With an experienced team of engineers and technicians, the company prioritizes research and development to ensure its products remain at the forefront of the industry. The Aluminum Profile Bracket is a testament to their unwavering pursuit of excellence, combining advanced materials, state-of-the-art manufacturing processes, and rigorous testing procedures.Recognized for its customer-centric approach, the company strives to provide exceptional support and service to clients around the globe. Their dedication to seamless integration, comprehensive technical assistance, and prompt delivery sets them apart from their competitors.Through continuous innovation and unparalleled precision, this company is shaping the future of structural support solutions, empowering industries to achieve new heights in efficiency, safety, and design.**Conclusion:**The Aluminum Profile Bracket stands as a groundbreaking solution that propels structural support applications into a new era. Its superior strength, flexibility, and adaptability make it an indispensable component in construction, industrial equipment, and furniture manufacturing. Alongside its corrosion resistance and aesthetic appeal, this bracket promises to revolutionize multiple industries by enhancing the safety, functionality, and aesthetics of structures worldwide. With the backing of an industry-leading company dedicated to innovation, the Aluminum Profile Bracket is set to redefine the standards of structural support solutions.

Aluminum C Profile Surging in Popularity as a Versatile Construction Material

Aluminum C Profile: The Versatile Solution for Your Construction NeedsAluminum profiles have revolutionized the construction industry, providing an affordable and lightweight solution that is both durable and adaptable. One of the most popular profiles in use today is the aluminum C profile, which offers a range of benefits for construction projects of all types.What is an Aluminum C Profile?An aluminum C profile is a hollow, aluminum extrusion that has a distinctive C-shaped cross-section. The profile's shape allows it to be easily customized and adapted for a variety of construction applications.Benefits of Aluminum C Profiles1. Lightweight but StrongOne of the main advantages of aluminum C profiles is that they are lightweight yet strong. The hollow design of the profile reduces its weight, making it easier to handle on the job site. However, because of its design and the high-quality aluminum used in its construction, the C profile is still incredibly strong.2. VersatilityAluminum C profiles are highly versatile. They can be used in a variety of applications, from constructing simple frames for partitions to creating complex structures like bridges. The C profile's design allows it to be easily cut and customized, making it suitable for use in a wide range of construction projects.3. Weather ResistantAluminum C profiles are highly resistant to weather, making them ideal for use in outdoor construction projects. They do not rust or corrode, even in harsh weather conditions, making them a durable and long-lasting solution.4. Low MaintenanceAluminum C profiles require very little maintenance. Once installed, they do not need to be painted or recoated, and they are resistant to fading, chipping, or cracking due to exposure to the weather.5. Eco-FriendlyAluminum is a highly sustainable material as it can be easily recycled. Aluminum C profiles are made from high-quality, recycled materials, making them an eco-friendly option for construction projects.Company IntroductionAs a leading supplier of aluminum profiles, {the company’s name} is committed to providing high-quality, affordable aluminum profiles that meet the unique needs of our clients.Our aluminum C profiles are manufactured with the highest quality materials to ensure durability, strength, and performance. We offer a wide range of standard and custom C profile sizes, enabling clients to find the perfect solution for their construction needs.Our team of experts is dedicated to providing personalized support to all clients, from initial consultation to project completion. We work closely with our clients to ensure that they receive the best possible solution and support.We pride ourselves on the quality of our products, and we are committed to providing competitively priced aluminum profiles that are both efficient and environmentally sustainable.ConclusionAluminum C profiles offer a range of benefits that make them an excellent choice for construction projects. Companies seeking versatility, durability, and affordability can rely on {the company’s name} to provide the highest quality aluminum C profiles that meet their needs. With our experienced team and competitive pricing, we are the ideal choice for all your aluminum profile needs.